-

iDock® 2.0 Delivers

-

myQ Enterprise

Digitally transform your loading dock with myQ Dock Enterprise.

Learn More -

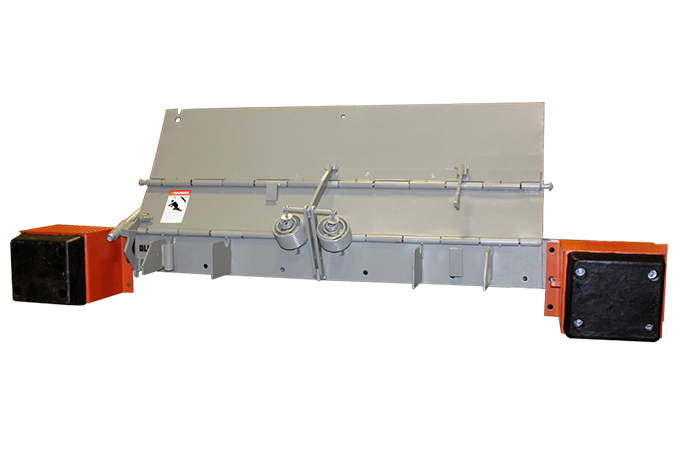

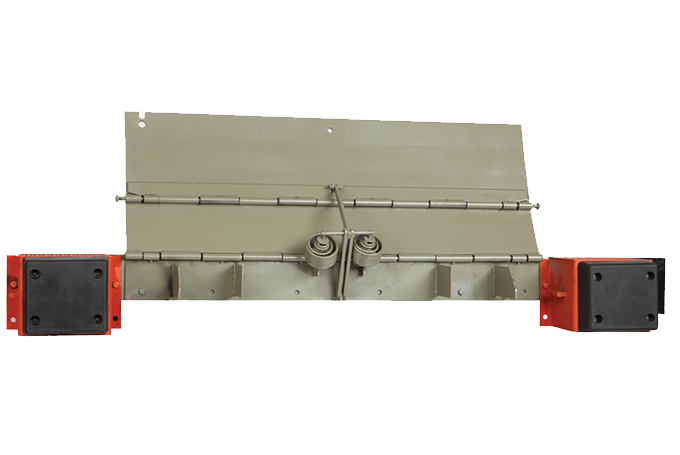

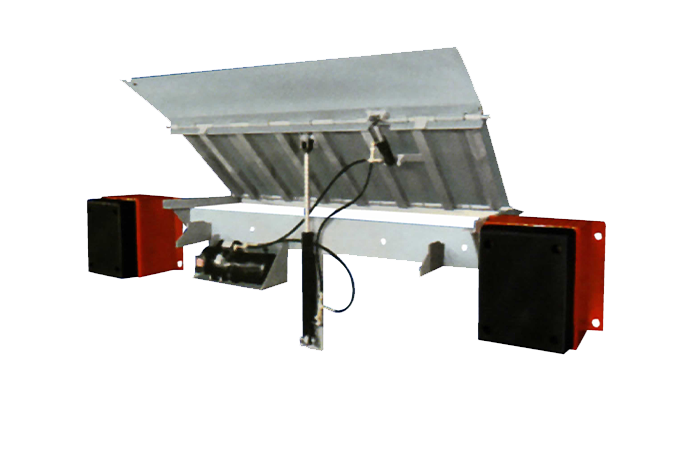

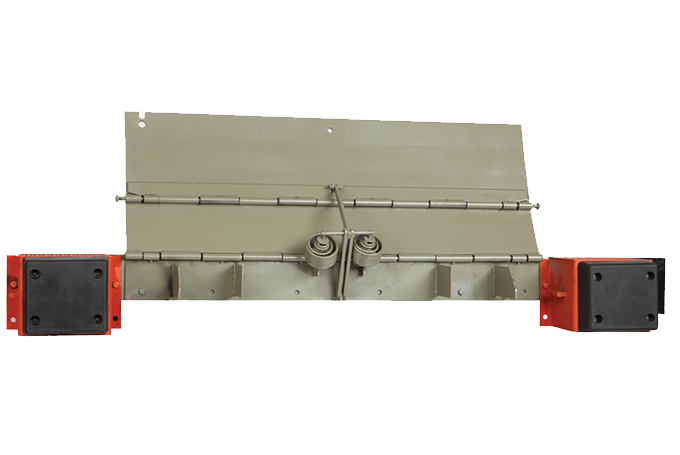

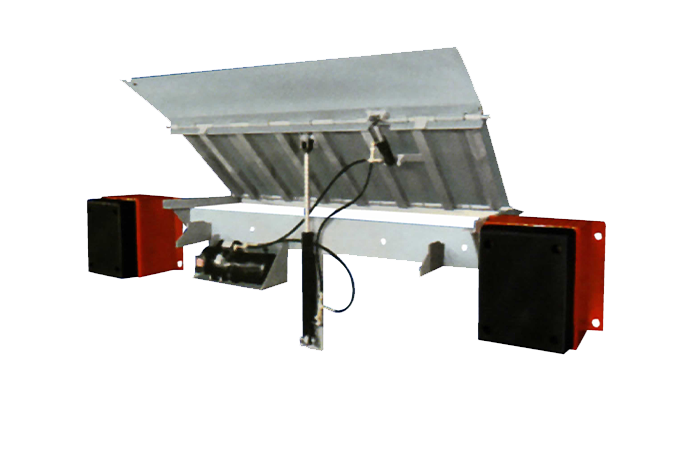

EDGE OF DOCK LEVELERS

The most effective and reliable EOD levelers in the industry.

Learn More -

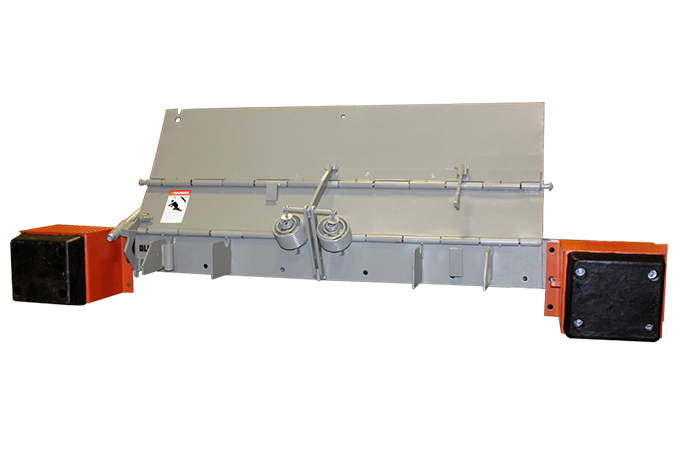

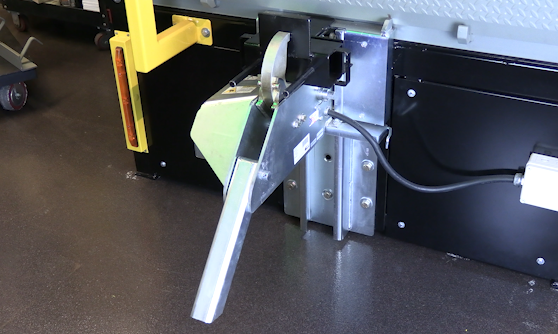

UNILOCK VEHICLE RESTRAINT

The Only Trailer-Positioned Restraint To Release RIG Wedge Without The Truck Reversing.

Learn More

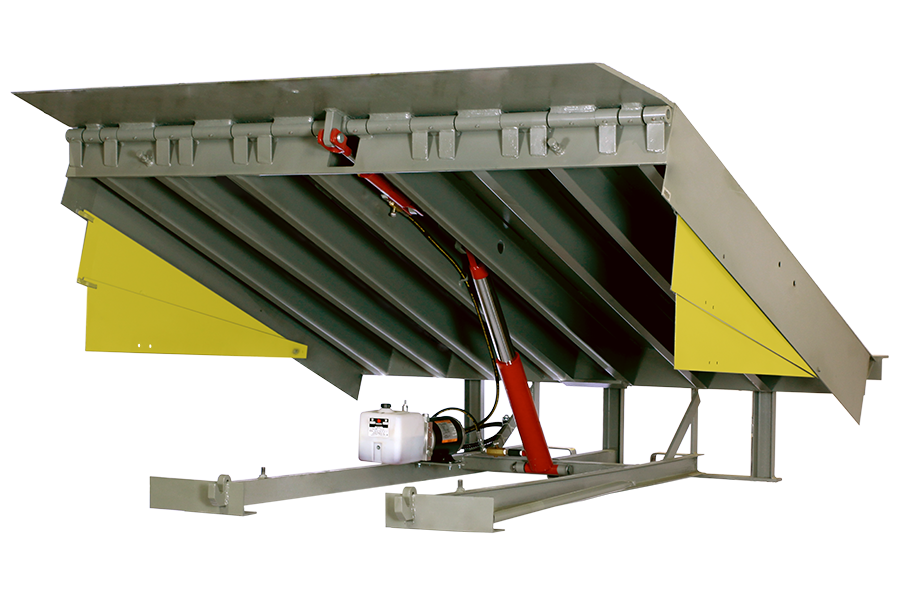

LOADING DOCK LEVELERS & EQUIPMENT

iDOCK CONTROLS

LEARN MORE

UNILOCK VEHICLE RESTRAINT

LEARN MORE

DLM EDGE OF DOCK LEVELERS

LEARN MORE

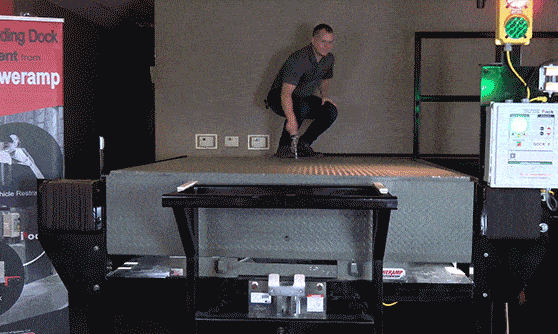

DLM YARD RAMP

LEARN MORE

myQ Enterprise

LEARN MORE

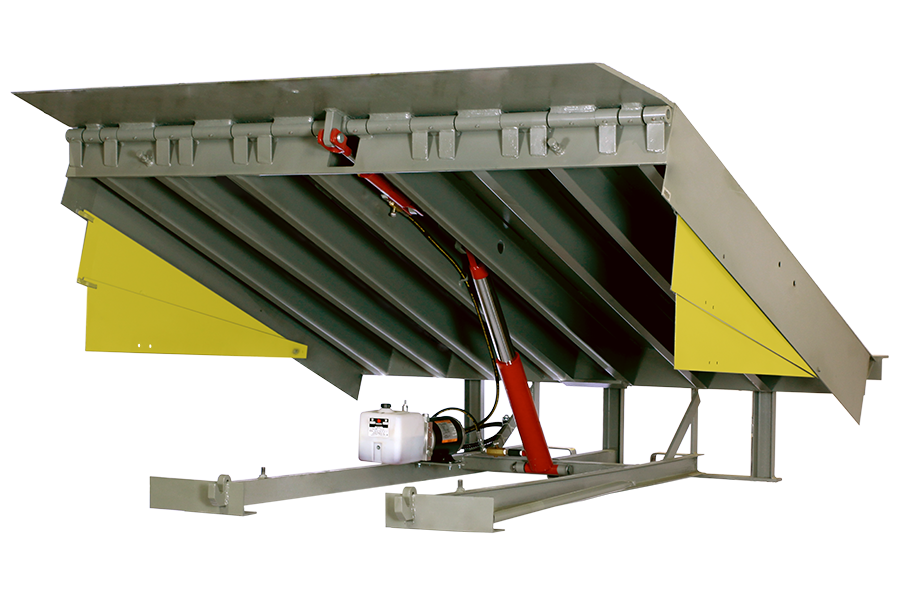

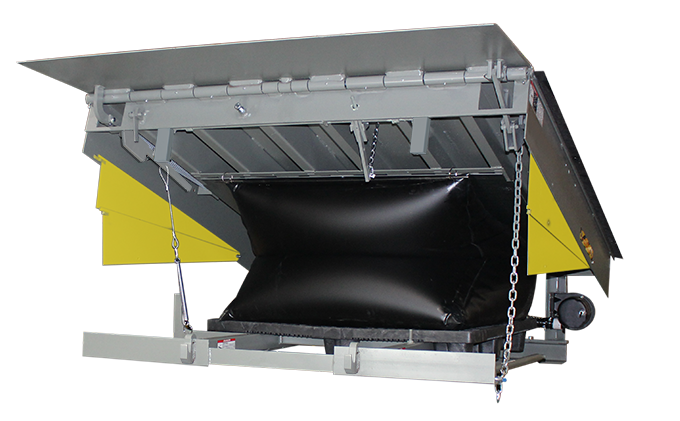

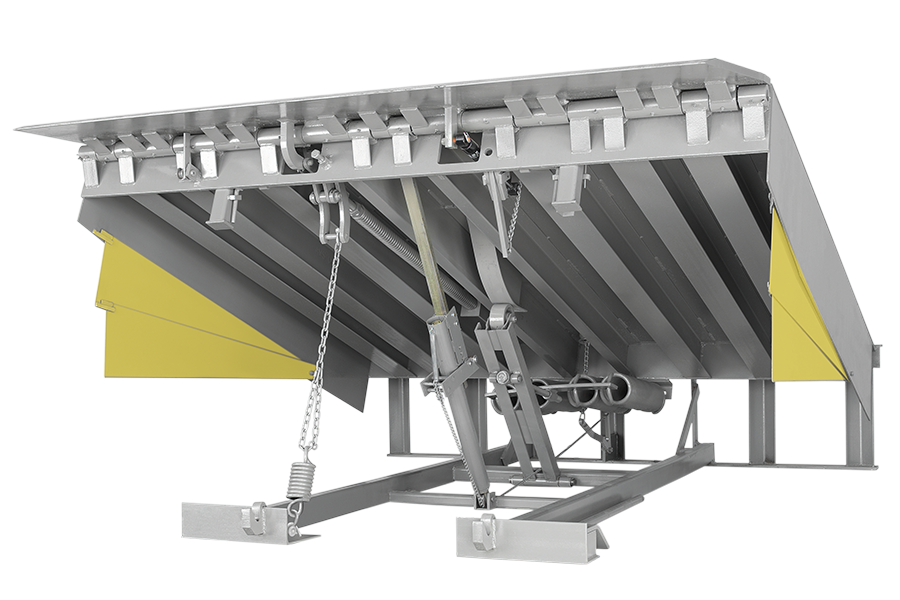

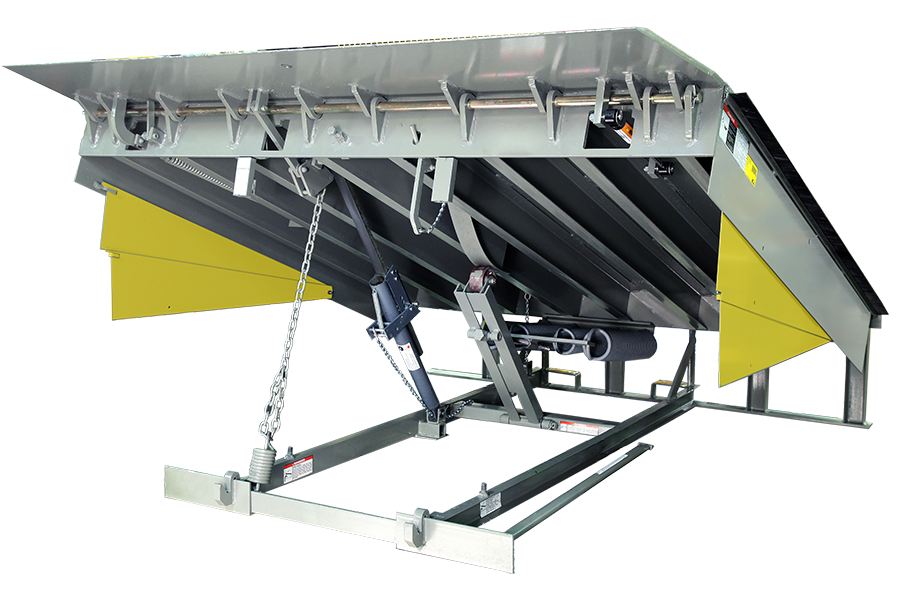

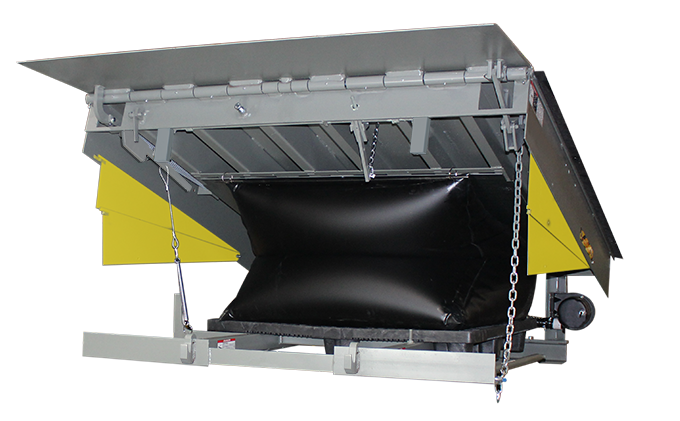

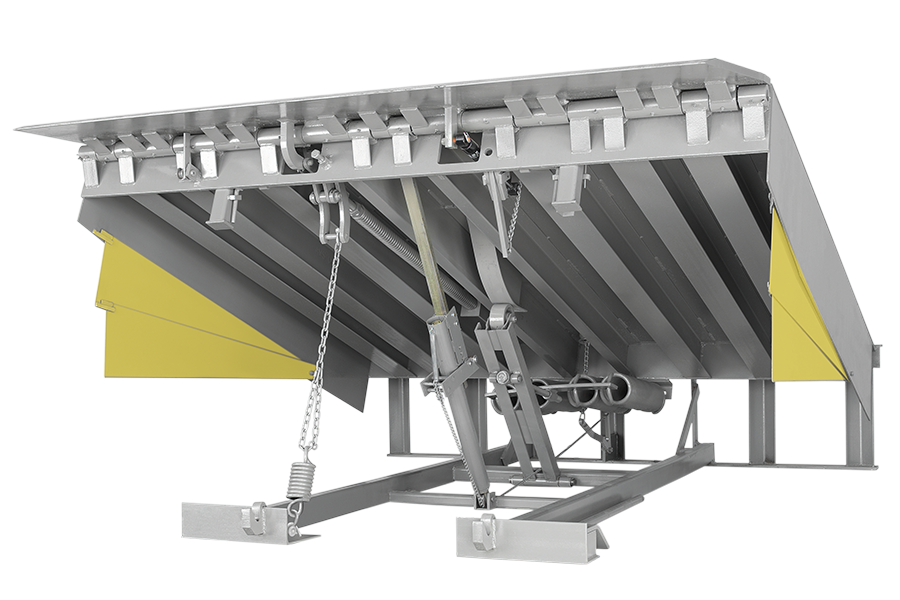

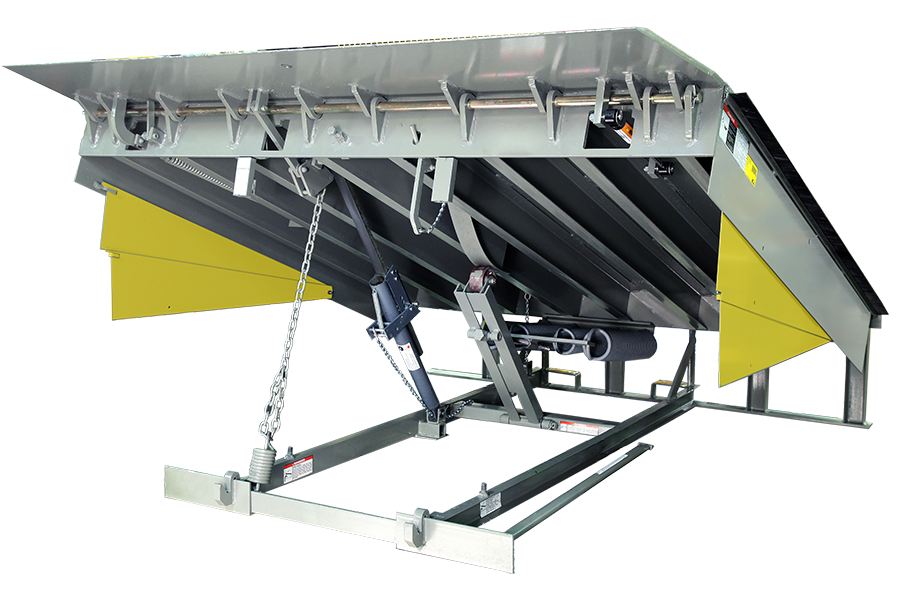

MECHANICAL DOCK LEVELERS

LEARN MOREINSTALLATION GALLERY

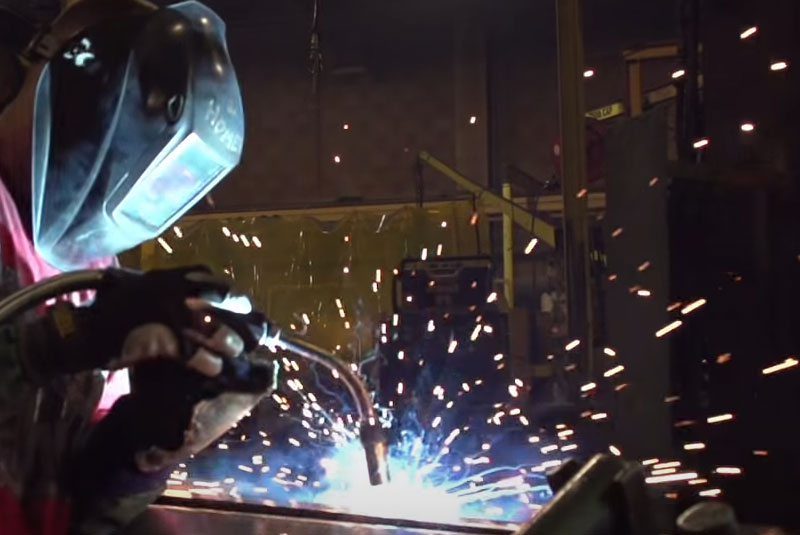

Want to see who else has used DLM dock equipment over the past 60 years? Click here to view installations of a variety of application types.

VIEW GALLERYINSTALLATION GALLERY

Want to see who else has used DLM dock equipment over the past 60 years? Click here to view installations of a variety of application types.

VIEW GALLERY